We faced this challenge with a novel idea graphitization

of the diamond surface with a gas excimer laser and creation of

nano-graphite layer of about hundred nanometers. The diamond surface

graphitization process is possible if the laser is absorbed by the diamond

surface and the intensity is tuned to make the transition diamond-graphite

thermodynamically favorite without ablating the material .

We realized a detector-grade diamond material with

graphitic electric contacts using a focused UV laser light. The

nano-graphitic layer was mechanically stable and electrically conductive

in both sides. The surface resistivity was measured with a multimeter and

was about 40 Ohms, in agreement with the literature values.

The response to a gamma- ray source of the detector were

measured for the first time. These preliminary measurements show that the

pad detector with graphitized contact is capable to detect ionizing

radiation in counting mode. A comparison was made between this detector

and a reference detector made of same quality diamond but metallic

electric contacts and no significant differences were seen.

The device was prepared by front and back irradiation of

the diamond surfaces with a 193 nm UV ArF excimer laser (Lambda Physik

LPX305i).

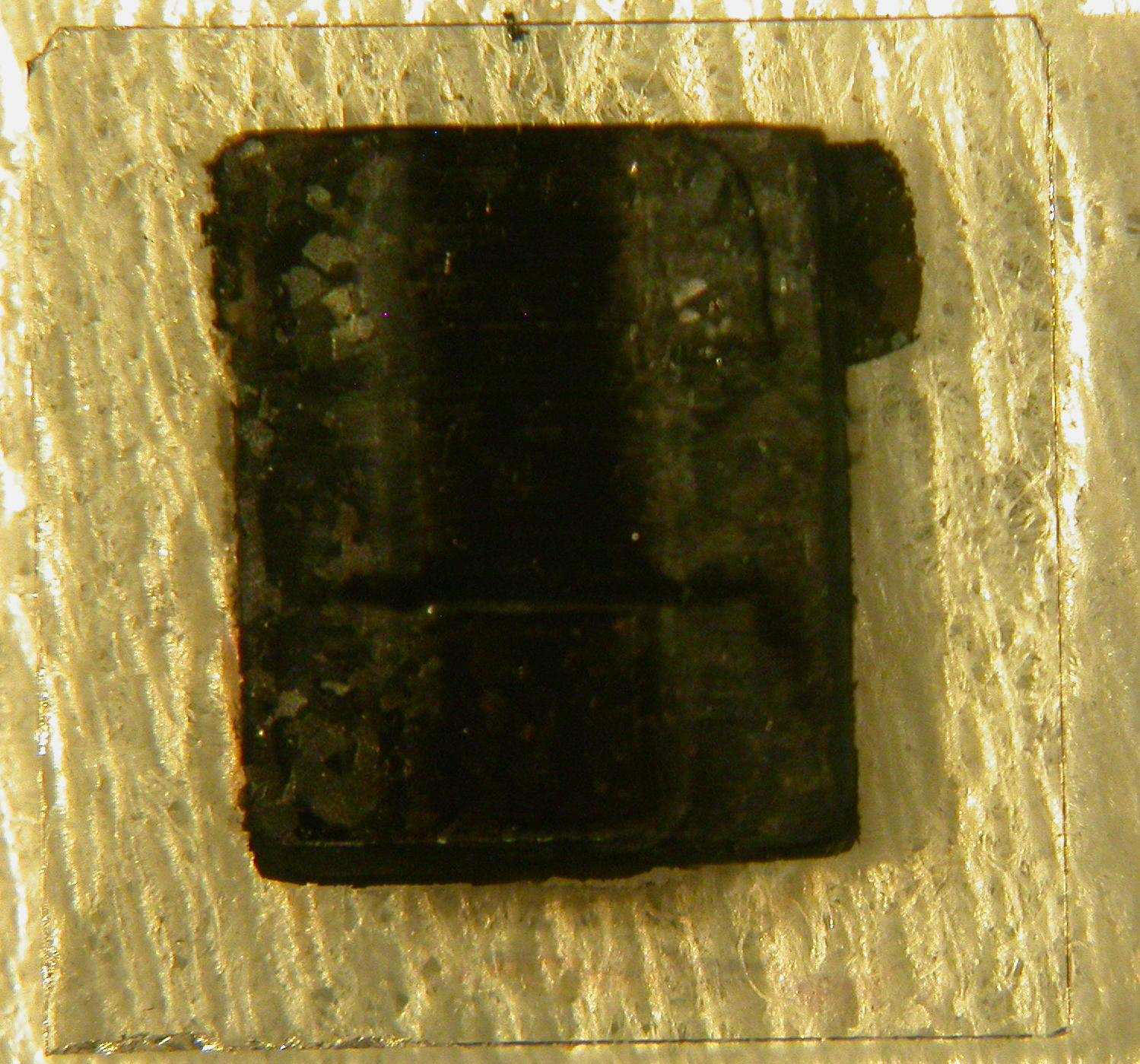

Figure 1.

Optical microscopy image of detector-grade poly-crystal CVD diamond with

dimensions 5x5x0.3 mm3

with photo-generated graphite electrical

contact made on the both sides.

The laser emitted 20 nsec long pulse with an energy of

about 160 mJ/pulse at 10 Hz repetition

rate. In order to focus the UV laser and reach therequired energy density

per pulse an appropriate UV focusing system was needed. The laser beam

with a transverse size of about 20

×10

mm2

,

was directed onto a homogenizer single matrix. The homogenized beam was

then directly projected via a thin and plain convex lens onto the sample.

The sample was placed in a holder and rigidly fixed to a

x-y movable stage. The x and y positions were controlled by two step

computer assisted motors.

The focused image was a square of 3 mm

2

at the sample surface and having a

local laser fluence of about 5 J/cm2

quite constant within the radiation

spot. The device was treated in air at room temperature and the surface

was scan at a velocity of about 0.3 mm/s to obtain a graphite electrode with a final total area of about 9 mm2 large enough to realize a pad detector.

This treatment was repeated on the other side of the surface sample (Figure 1) in order to realize

a solid state radiation detector in planar configuration. The device was fixed between two gold made clamps in order to apply the high voltage by

a SMA connector and enclosed in an aluminum box to electrically

shield it.

The reference device was a commercially available

poly-crystal diamond detector of the same size 5x5x0.3mm

3

and material quality but with DLC/Pt/Au electrical contacts

fabricated on both faces (planar configuration) with proprietary contact

technology. The detector was glued on a printed circuit board in one side

and the two electrodes wire bonded to a SMA connector and enclosed also in

an anodized aluminum box.

A low intensity

60Co

gamma-ray source was placed above the detectors at a distance of 1 cm in

air at room temperature. The front-side electrode was used as the signal

output and connected, through ORTEC charge sensitive preamplifier and

spectroscopy amplifier ( 100mV/fC total gain and 0.5

μs shaping-time ), to an

oscilloscope and waveforms were recorded by GPIB protocol.

Figure 2. Single gamma response to

60Co

gamma source from reference diamond detector (waveforms a) and from

diamond detector with laser-graphitized electrodes (waveforms b) for an

applied voltage of about 300 V

Figure 2 shows the response of the two devices to gamma

radiations. The response is very similar showing that the nanographitic

layer is not a source of minority carriers trapping. This preliminary

result is very important to establish the good charge injection and

collection properties of the contacts, in addition to mechanical adhesion

and mechanical stability.